Bringing Award-Winning Technology to Your Project

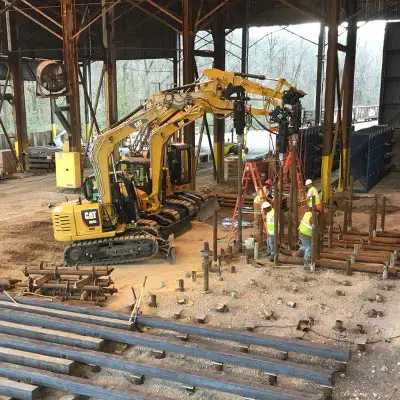

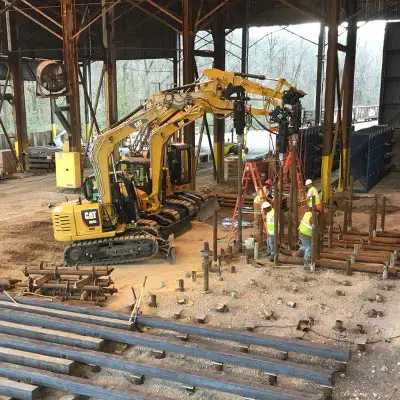

The Fuller Pile™ System was invented by Andrew C Fuller, a Low Country resident and the owner of Claycor Contractors, Inc. He established his renovation and restoration business 24 years ago before becoming certified in the installation of helical piles. Andrew was gradually introduced to the challenges of installing these pilings in residential settings.

Need Leads to Development

Introducing The Fuller Pile™ System:

- Developed by Andrew after 4 years of extensive research and experimentation.

- Addresses the inherent problems of pressure grouted micro-piles and helical piles.

- Ensures safer code-compliant hybrid piles for clients.

- Patented in the United States, Canada, and Mexico.

Stronger Than Ever

Introducing the Enhanced Fuller Pile™ System:

- Incorporates Andrew's latest ideas after a 1.5-year study at The Citadel.

- Validated by Citadel researchers and national foundation experts as fully code compliant.

- Now even stronger and more ductile with new design details for added lateral resistance and seismic resilience.

- Offers pile capacities ranging from 40 tons to 200 tons per pile, with flexural capacities exceeding 200 k-ft for the largest standard piles.

- Standard helical piles typically have lateral capacities of approximately 5% of this value in many cases.

- Our ongoing research aims to achieve the ultimate goal of 800 tons of axial load per pile.

Not a Helical Pile

Helical piles often present performance concerns, with limited lateral resistance and seismic ductility. The Fuller Pile™ System, while installed similarly to helical piles, is a hybrid pile that meets the 2021 International Building Code. Its axial capacity is calculated and tested like any other cast-in-place pile system, relying on skin friction for geotechnical strength, not end bearing. All components are designed to meet code provisions, including seismic ductility, liquefaction, and kinematic load resistance.

Key Points:

- Helical piles have performance issues, leading many structural engineers to avoid them.

- Some jurisdictions, like California, prohibit helical piles for new construction due to seismic failure evidence.

- Helical piles lack lateral resistance, seismic detailing, and have questionable vertical capacities based on installation torque values.

- The Fuller Pile™ System is not a "helical pile" but a hybrid pile, fully compliant with the 2021 International Building Code.

- Installation is similar to helical piles, but performance is independent of the installation method.

- Fuller Pile™ System's axial capacity is calculated and tested like other cast-in-place piles, with geotechnical strength from skin friction.

- All components designed and detailed to meet code provisions, including seismic ductility, liquefaction, and kinematic load resistance.